- Home

- About Us

- Products

- Rohmann Eddy Current

- Dakota Ultrasonics

- DeFelsko Corporation

- Secu-Chek UV-LED Lamps

- Sonotec Ultrasonic Solutions

- Integrated Design Tools (IDT Vision)

- Hoffmann Tam Panels

- Sonotec Ultrasonic Hand-Tools

- G.A.L. Gage Company

- Western Instruments Inc.

- Novotest

- Esders Gas Technology

- Desoutter Industrial Tools

- Hinode Electric

- Remote Viewing Inspection

- H.G. Tools Co., LTD

- LED Lighting

- Industrial Supplies

- Disposable Masks

- Reusable Face Masks

- Foldable Safety Helmet

- Polycarbonate Face Guard

- Strainers

- Compressors

- Hoses

- Pipes

- Air Cool Jacket

- Compact Tarp Stretcher

- Floor Graphic Sheet

- Portable Water Tank

- Sound Signage

- Sandless sandbag

- TiO2 (Self-cleaning) Membrane Fabric

- GENTOS

- Remote Area Lighting Systems

- Aircraft Cutting Tools

- Adhesive Tape

- Nabond Nanofiber Electrospining Unit

- Proceq NDT

- HED International

- Raw Materials

- Reference Standards

- News

- Contact Us

(65) 6878 0608  (65) 6878 0609 |

Wall thickness measurement as part of non-destructive testing is one of the most common uses of ultrasonic technologies. In addition to the classic measurement of wall thickness as part of quality control, our precise wall thickness measurement devices can also be used to detect damage caused by erosion and corrosion on, for example, ships, storage tanks, pipelines and cranes. We have a variety of versions of our devices for all types of applications.

Detailed Product Information:

The light and compact ultrasonic wall thickness gage SONOWALL 50 enables the precise measurement of the wall thickness of components made of metal, glass, ceramics and plastics. This efficient device allows the measurement of materials with both flat and curved surfaces. The wall thickness gauge enables the quick and simple detection of the first signs of wear and corrosion, for example, on ships, storage tanks, pipelines and cranes etc.

The SONOSCAN probe SW 5-22 is characterised by its stable data readout and broad measuring range. The integrated data logger makes this user-friendly device a powerful and efficient all-rounder for practical use in numerous applications. In addition to the robust aluminium housing and the use of the highest quality components and materials, the SONOWALL 50 also has a practical ergonomic design.

The SONOWALL for the SONOWALL 50 has been specifically designed for the measurement of wall thicknesses of pipes with small diameters. The integrated guidance system guarantees the stable coupling at curved pipe surfaces.

The light and compact ultrasonic wall thickness gauge SONOWALL 60 uses multi-echo technology in order to enable reliable and precise measurement through painted surfaces and surfaces with protective coatings. Simple calibration allows the use of the device with most materials. The wall thickness gauge is simple to operate and has been specifically designed for the measurement of wall thicknesses of metal components. The SONOWALL 60 can be used for the reliable measurement of pipes, tanks, pressurised containers, machinery components and steel parts. A zero-point adjustment is not necessary. The robust, waterproof device can also be used for the quick, precise and reliable measurement of rough and uneven surfaces.

The new thickness gauge is perfectly suited for various ultrasonic thickness applications. The robust aluminium casing with IP 67, a light weight of only 990g and high resolution anti-glare 5-inch graphic display make the SONOWALL 70 the ideal thickness gage in harsh test environments.

Intuitive operation

In addition to high performance, the focus during the development for this new thickness gage was on intuitive handling and clear display of measurement results. An intuitive user interface, clearly structured menu, and the presentation of all menu items in full text simplify and accelerate the set-up and opertation of the device, and reduce the risk of incorrect settings.

All relevant measurement values and device settings such as wall thickness, A- or B-Scan, and individually adjustable test parameters are apparent at a glance on the large display screen (800×489).

Thanks to the innovative flip-screen technology, the device can be used with either hand for convenient working.

Intelligent probe identification

SONOWALL 70 is the first thickness gage in the market with intelligence probe identification. The extended probe management allows probe-specific information, such as DAC-curves, delay lines and serial numbers, to be saved directly in the probe.

In addition to various thickness applications, the device can be upgraded to a full-function flaw detector.

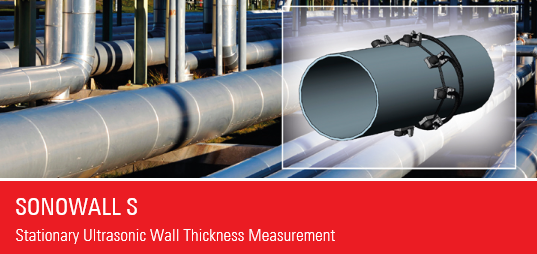

Pipes in industrial environments are generally exposed to typical signs of wear such as abrasion or corrosion, leading to a constant decrease of the wall thickness. To meet the high safety requirements in refineries, chemical plants and power stations, the wall thickness of pipes has to be checked regularly.

The measurement points are often difficult to reach and lifting platforms or scaffoldings are necessary for the manual testing procedure. In addition, the pipe insulation and other jackets have to be stripped off and replaced after every testing process. This generates significant costs for the plant operator.

The permanent installation of a stationary measuring solution could dramatically minimize these expenditures. Once the sensors are installed, the operator can easily access a ground level terminal box with a standard flaw detector such as the SONOSCREEN ST10 to check the respective wall thickness. The number of sensors usually depends on the pipe diameter and can be selected to the exact needs of the customer.

The SONOWALL S is a smart and extremely reliable solution to efficiently perform frequent wall thickness inspections at pipes.

The compact and light ultrasonic wall thickness gauge CYGNUS 1 EX uses multi-echo technology in order to enable reliable and precise measurement through painted surfaces and surfaces with protective coatings. The device is intrinsically save and was particularly developed for the simple testing of the wall thickness of materials such as metal, glass, ceramics and plastics in areas with risk of explosion. The CYGNUS 1 EX can be used for the measurement of gas pipes, pipelines, oil tanks, pressurised containers, machinery components and steel parts. A zero-point adjustment is not necessary.

The robust, waterproof device can also be used for the quick, precise and reliable measurement of rough and uneven surfaces.

II 1G Ex ia IIC T2/T3/T6 Ga

I M1 Ex ia I Ma

The CYGNUS 1 EX is also suitable for use in mining.

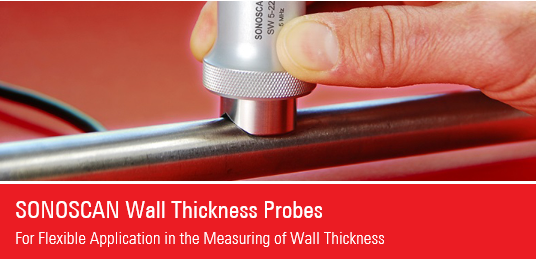

The ergonomically-designed SONOSCAN wall thickness probes for non-destructive testing (NDT) are designed for use with our SONOWALL devices for the precise measurement of wall thicknesses. The probes are efficient, robust ultrasonic transducers that can be used in conjunction with all standard ultrasonic testing devices.

Due to their variety of design and size, SONOSCAN probes are optimally suited for a multitude of applications. For example, the SONOSCAN SW 5-22 for the SONOWALL 50 has been specifically designed for the measurement of wall thicknesses of pipes with small diameters. The integrated guidance system guarantees the stable coupling at curved pipe surfaces.

The unique and practical ergonomic design of the wall thickness probes enables comfortable and convenient use. In addition to our standard products, we can also manufacture customer-specific solutions.