- Home

- About Us

- Products

- Rohmann Eddy Current

- Secu-Chek UV-LED Lamps

- Sonatest

- MR Chemie

- NOVO DR

- Hoffmann Tam Panels

- Desoutter Industrial Tools

- Novotest

- Integrated Design Tools (IDT Vision)

- Dakota NDT

- DeFelsko Corporation

- Sonotec Ultrasonic Solutions

- Sonotec Ultrasonic Hand-Tools

- G.A.L. Gage Company

- Western Instruments Inc.

- Esders Gas Technology

- Yoancomposite

- Hinode Electric

- Services

- News

- Contact Us

(65) 6878 0608  (65) 6878 0609 |

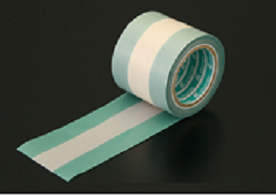

Adhesive tape specially developed for covering the heater on the heat-sealing machine.

Since the adhesive is not applied on the center of the tape, it can help the heater not to get the adhesive materal directly, and it hences the dirt and adhesive residue on the tape. It turn out to make the service life of the tape longer.

Use

●Easy to release from heat-sealing mold.

●Easy to release from press plates such as cotton and non-woven fabric.

●Electric insulation covering at high temperature

●Using temporary fixing tape for joining cables

Operating temperature limit

-60°C to +200°C

Structure

Characteristics

●Since the adhesive is not applied on the center part of the tape, the glue would not melt for high temperature.

●Since attached serface is small, easy to remove it from the object and great for use of temporary jointing.

●The surface of the tape has excellent anti-adhesion qualities as well as release property, sliding property, chemical resistivity, and water-repellent property.

●Excellent electric insulation and dimensional stability.

General dimensions table

| General thickness (mm) | Width (mm) | Length (m) |

|---|---|---|

| 0.13 | 38 (Part of the tape without any adhesive material 20) 50 (Part of the tape without any adhesive material 20) |

10 |

*For the sizes other than the ones mentioned above, discuss separately.

General traits table

| Product number | General thickness (mm) | Adhesive strength 180° peeling (N/25mm) | Tensile strength (N/25mm) | Maximum operating temperature (°C) |

|---|---|---|---|---|

| AGF-102 | 0.13 | 9 | 380 | 200 |

*The characteristic values given in the table are the measured values, and not the standards.

*Adhesion is a measure of adhesive force on the side with adhesive material.

*The maximum temperature of substrate is 260°C.

*Nominal thickness is the total thickness of the part with adhesive material.