- Home

- About Us

- Products

- Rohmann Eddy Current

- Secu-Chek UV-LED Lamps

- Sonatest

- MR Chemie

- NOVO DR

- Hoffmann Tam Panels

- Desoutter Industrial Tools

- Novotest

- Integrated Design Tools (IDT Vision)

- Dakota NDT

- DeFelsko Corporation

- AVIONICS

- Sonotec Ultrasonic Solutions

- Sonotec Ultrasonic Hand-Tools

- G.A.L. Gage Company

- Western Instruments Inc.

- Esders Gas Technology

- Yoancomposite

- Hinode Electric

- Services

- News

- Contact Us

(65) 6878 0608  (65) 6878 0609 |

Overview

Knowing the state of conservation of wooden elements is fundamental for the restoration and structural rehabilitation of historic and artistic buildings.

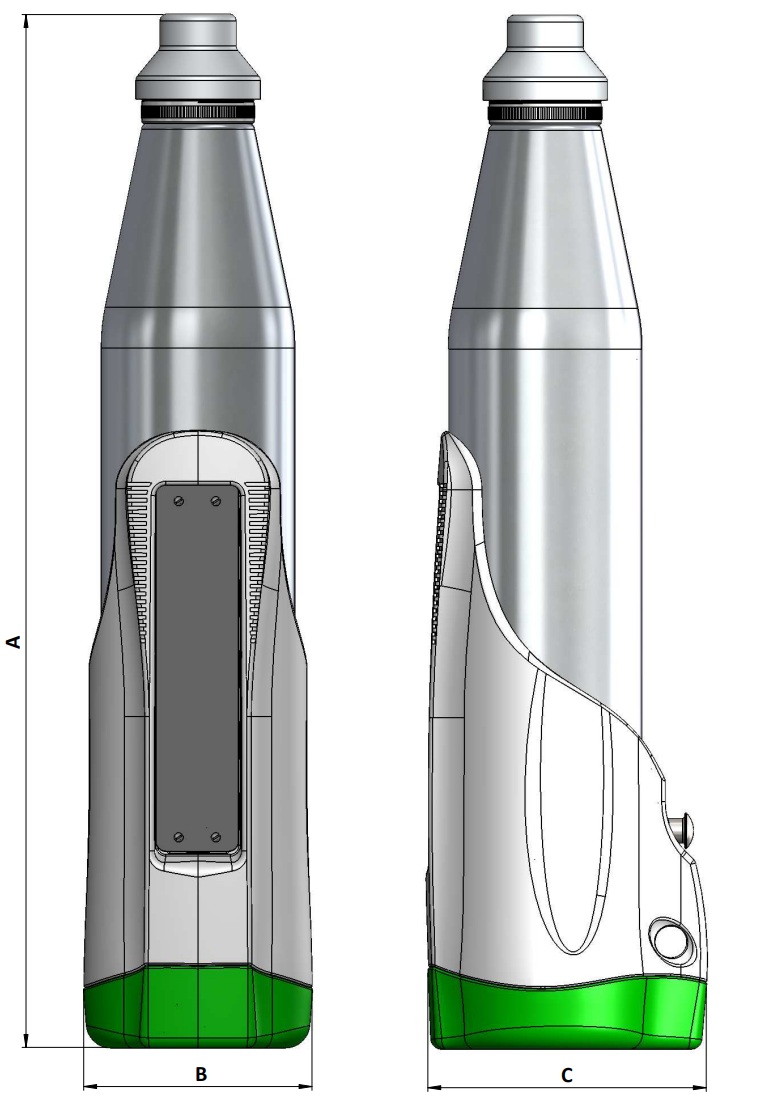

The WoodPecker complements a Type N concrete hammer, featuring a hardened and ground steel needle (60 HRC hardness), 2.5 mm in diameter, 50 mm long, and a truncated conical tip with a 35° inclination angle. This instrument, entirely made in Italy, is ideal for assessing the state of conservation of wooden elements in buildings of historical and artistic interest.

The need to develop a non-destructive technique capable of assessing the conservation state of a wooden element and its residual mechanical properties (strength and deformability parameters) led to the creation of a practical and easy-to-use tool that provides reliable information on material quality.

The WoodPecker is an adaptation of an N-type Schmidt hammer for concrete, to which a tempered and ground steel needle is added (hardness 60 HRC), with a diameter of 2.5 mm, length of 50 mm, and a truncated conical tip with a 35° taper angle at the end.

This tool is notable for being compact, durable, and at the same time easy to handle: weighing approximately 1100 grams, it is ideal for immediate use on materials already in place.

The WoodPecker is a Made in Italy product.

Features

-

Operating Principle

The needle is driven into the wooden element with a predetermined number of impacts.

The depth of penetration can be correlated with the mechanical properties of the wood and its state of preservation.

Penetration depth is measured using a dedicated detection system, known as an analog dial gauge.

After the measurement is taken, the needle can be easily removed from the wood, and the minimal trace left by the imprint can be easily sealed.

The calibration of the Schmidt hammer can be verified using a calibration anvil.

-

Fields of Application

Assessing the state of preservation of wooden elements is especially important during restoration or structural rehabilitation of buildings with historical or artistic value.

In such cases, for conservation and integrity reasons, it is not possible to extract even small core samples from the wood elements.

Knowing the condition of the entire cross-section is crucial, as in most situations, the effects of wood-degrading organisms—such as fungi, wood-boring insects, and molds—are not externally visible.

Performance

| RANGE | 5-120 N/mm2 |

| IMPACT ENERGY | 2,207 Nm |

| LIMIT | Thickness > 100mm |

Mechanical

| EXTERNAL PART | Aluminium 6060 – 11S |

| IMPACT COMPONENTS | Carbon steel |

| HEAT TREATMENT | Chemical carbonitriding NIT-OX |

| SLIDING COMPONENTS | Stainless steel AISI 303 |

| GRIP | Glass-filled nylon |

| NEEDLE | Case-Hardened Steel |

Physical

| Dimensions | (A) 300 x (B) 70 x (C) 70 mm |

| Weight | 1.3 kg |

The kit includes:

- WoodPecker wood Schmidt hammer

- Dial gauge system, 50 mm range, 0.01 mm resolution

- 50 steel needles

- Wall-marking pencil

- DRC survey data sheet

- Operating Manual

- Calibration Report

- IP67-rated hard transport case

Package

| DIMENSIONS | 340 x 280 x 180 mm |

| WEIGHT | 4.0 kg |