- Home

- About Us

- Products

- Rohmann Eddy Current

- Secu-Chek UV-LED Lamps

- Sonatest

- MR Chemie

- NOVO DR

- Hoffmann Tam Panels

- Desoutter Industrial Tools

- Novotest

- Integrated Design Tools (IDT Vision)

- Dakota NDT

- DeFelsko Corporation

- AVIONICS

- Sonotec Ultrasonic Solutions

- Sonotec Ultrasonic Hand-Tools

- G.A.L. Gage Company

- Western Instruments Inc.

- Esders Gas Technology

- Yoancomposite

- Hinode Electric

- Services

- News

- Contact Us

(65) 6878 0608  (65) 6878 0609 |

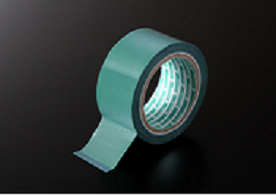

It has a higher tensile strength than ASF-115 (MX) by applying high strength and low elongation fluoroplastic film as the base material.

Use

●Roll masking for extrusion lamination

●Electric harnesses

●Insulating tape

●Lining for the friction surface

●Identification

Operating temperature limit

-60°C to +250°C

Structure

Characteristics

●Highest heat resistance in the ASF series.

●The elongation is lower than those of ASF-110 FR and ASF 115 (MX).

●Green in color.

●The surface of the tape has excellent anti-adhesion qualities as well as releace property, and sliding property.

●Excellent electric insulation and weather resistance.

●Meets UL510 standard.

General dimensions table

| Total thickness: mm(in) | Width: mm(in) | Length (m) |

|---|---|---|

| Normal stock | ||

| 0.10(0.0039) | 34, 38, 50, 75 (1.3, 1.4, 2, 3) |

33 |

*Maximum width is 75 mm.

*For the sizes other than the ones mentioned above, discuss separately.

General traits table

| Product number | Total thickness mm(in) |

Tensile strength N/25mm(lbs/in) |

Elongation (%) |

Adhesion 180°peel test N/25mm (oz/in) |

Breakdown voltage/ substrate only (kV) |

Maximum operating temperature °C(°F) |

|---|---|---|---|---|---|---|

| ASF-118A FR | 0.10(0.0039) | 220(49) | 70 | 7(24) | 10 | 250(480) |

*The characteristic values given in the table are the measured values, and not the standards.