- Home

- About Us

- Products

- Rohmann Eddy Current

- Secu-Chek UV-LED Lamps

- Sonatest

- MR Chemie

- NOVO DR

- Hoffmann Tam Panels

- Desoutter Industrial Tools

- Novotest

- Integrated Design Tools (IDT Vision)

- Dakota NDT

- DeFelsko Corporation

- AVIONICS

- Sonotec Ultrasonic Solutions

- Sonotec Ultrasonic Hand-Tools

- G.A.L. Gage Company

- Western Instruments Inc.

- Esders Gas Technology

- Yoancomposite

- Hinode Electric

- Services

- News

- Contact Us

(65) 6878 0608  (65) 6878 0609 |

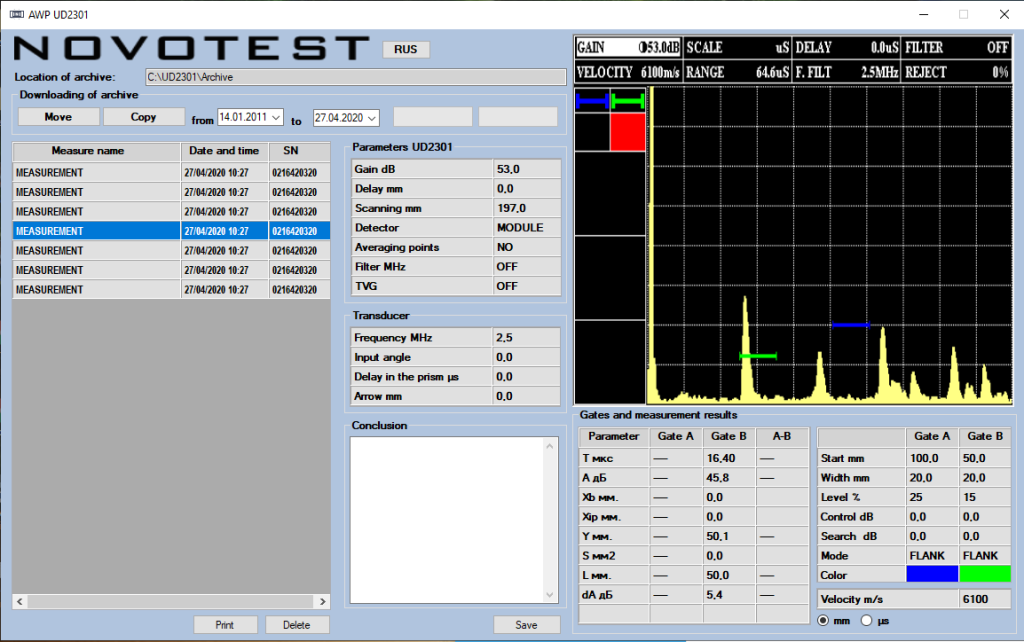

Ultrasonic Flaw Detector NOVOTEST UD2301

An ultrasonic flaw detector is designed to search for voids and inhomogeneities inside the materials under testing with ultrasound. It is the most common device in the world for non-destructive testing of metal (and other materials with low attenuation of ultrasonic waves) products in production, as well as objects in operation.

Ultrasonic Flaw Detector NOVOTEST UD2301 is a powerful, ergonomic, portable device that has all the functions of a general industrial ultrasonic flaw detectors and can be used in laboratories and workshops, and is perfect for field use.

The main advantages of the Ultrasonic Flaw Detector NOVOTEST UD2301 are below:

- MULTIFUNCTIONAL

The device has wide functionality:

– presentation of the signal like A-scan and B-scan, which allows the operator to select the desired operating mode in accordance with the task;

– the device has two independent gates, with the ability to evaluate parameters in different areas on the scan, also using the automatic defect alarm function the limits can be configured individually for each gate.

– for better signal processing, the device has functions of freezing and envelope, which allows the user to more accurately evaluate the received data.

- DAC AND TVG FUNCTIONS

The device implements the Distance Amplitude Correction (DAC) and Time Varied Gain (TVG) functions, with the setting up to 16 points, which allows the operator to evaluate the equivalent reflector size at various depths.

- DGS FUNCTION

Also in the device there are Distance Gain Size (equivalent) diagrams that allow user to build an amplitude curve from one standard reflector, as well as calculate the equivalent reflector size of tested discontinuities.

- ARCHIVE

The device has an archive for storing measurements, settings for a specific object, settings of transducers to quickly switch settings when changing the testing object .

- ANY DISPLAY ORIENTATION

A unique screen orientation function is implemented in the Ultrasonic Flaw Detector NOVOTEST UD2301, depending on the conditions under which the testing is performed, the screen orientation can be either vertical or horizontal. Also, the screen can be configured for both right-handed and left-handed people, i.e. the screen can be rotated 360°.

- AUTONOMY

The device powered from three standard AA batteries, which makes the device completely independent of the stationary power source, the internal charger allows the battery to be charged from the standard USB 5V socket, with power bank the device can be used continuously for almost unlimited time.

- DESIGN

The device has a transflective TFT display with a resolution of 480x320px, the enclosure is made in an ergonomic shape with a rubber bumper, which makes the device shockproof and resistant to falls. To connect the probes, standard connectors are used, which allows the operator to use any transducers without restrictions.

The device is supplied with PC software for uploading the measurement archive and processing the results.

Advantages:

- Superbright display with which it is comfortable to work outdoors on a sunny day;

- Frequency range from 0 to 10 MHz, with smooth adjustment;

- Display of a scale of scanning in microseconds and millimeters;

- Construction and processing A-scan and B-scan;

- The presence in the device of the operating mode of the DAC curves (construction of 16 points);

- Existence in the device of TVG mode (construction of 16 points);

- DGS function, with automatic calculation of the equivalent reflector size;

- Archive of measurements, settings, transducers with the ability to transfer data to a PC;

- Any side display orientation options that allow user to work in any position of the device;

- The device operates on standard AA batteries, as well as on conventional batteries, which makes them easy to replace;

- The NOVOTEST UD2301 flaw detector can be powered by a universal mobile battery (power bank) via a mini USB connector;

- Ergonomic shockproof case with protective rubber protectors;

- Light weight and compact size.

| specifications | |

| Operating frequency range | from 1 to 10,0 MHz |

| Range of measured time intervals (duration of scanning) | from 6 to 1000 µs |

| Velocity range | 1000 – 9999 m/s |

| Error of measurement of time intervals | not exceed ± 0.025 µs |

| Maximum permissible error of measurement of the amplitudes of the signals at the receiver input in the range from 0 to 110 dB | not exceed ± 0.5 dB |

| Testing gain range | 125 dB |

| Averaging over the quantity of starts | from 1 to 16 |

| Range of variation of temporal sensitivity adjustment (TVG) | 40 dB |

| Number of control points TVG | 16 |

| Duration of the excitation pulse to the load | from 0.0 to 0.5 µs |

| Deviation of the amplitudes of input signals in the range from 10 to 100% of the screen height not more than | 1 dB |

| Setting a delay in the prism of the probe | from 0 to 15 µs |

| Detection of signals | positive half-wave, radio mode |

| Standards | EN 12668 ASTM E1324 EN 55011 EN61000-6-2:2001 EN 61010-1:2014 (EN 61010-1:2010) EN 60529:2014 EN ISO 16810:2016 SOU NNEC 027:2014 SOU NNEC 032:2014 SOU NNEC 038:2017 |

| Dimensions (W*H*L) | 80*162*38 mm |

| Weight, not more | 250 g (without batteries) |