- Home

- About Us

- Products

- Rohmann Eddy Current

- Secu-Chek UV-LED Lamps

- Sonatest

- MR Chemie

- NOVO DR

- Hoffmann Tam Panels

- Desoutter Industrial Tools

- Novotest

- Integrated Design Tools (IDT Vision)

- Dakota NDT

- DeFelsko Corporation

- AVIONICS

- Sonotec Ultrasonic Solutions

- Sonotec Ultrasonic Hand-Tools

- G.A.L. Gage Company

- Western Instruments Inc.

- Esders Gas Technology

- Yoancomposite

- Hinode Electric

- Services

- News

- Contact Us

(65) 6878 0608  (65) 6878 0609 |

Ultrasonic Thickness Gauge NOVOTEST UT-1M-ST

Ultrasonic Thickness Gauge NOVOTEST UT-1M-ST is a special version of the thickness gauge in a metal enclosure, which is designed for extreme operating conditions, when there is a possibility of the device dropping or other damage of the unit during operation. The durable aluminum bodie’s profile withstands high static and dynamic compression loads, which allows the operator to use the device “carelessly”.

Ultrasonic Thickness Gauge NOVOTEST UT-1M-ST is designed to measure the thickness of products with low attenuation of ultrasonic vibrations, with one-way access to them during their manufacture and operation.

Some advantages of Ultrasonic Thickness Gauge NOVOTEST UT-1M-ST:

- WIDE RANGE OF THICKNESS OF TESTING PRODUCTS

Same as other ultrasonic thickness gauges TM “NOVOTEST”, Ultrasonic Thickness Gauge NOVOTEST UT-1M-ST allows user to measure the thickness of products in a wide range with a minimum set of transducers, this is achieved thanks to the advanced settings of the device (amplification of two stages, V-correction, etc.)

- UNIVERSAL TRANSDUCERS

Any dual-element probes can be connected and configured to the device by cables with standard connectors. What makes Ultrasonic Thickness Gauge NOVOTEST UT-1M-ST universal to use, and does not limit users in choosing a probes for operation.

- DISPLAY THE PRODUCT PROFILE WHEN SCAN

The device has a scanning mode of the product in the mode of a B-scan, which allows user to visualize thinning and thickening of the wall like a graph on the display of the device. This allows the user to see the product profile, which simplifies the operator’s work. Additionally, there is an alarm function for exceeding the maximum and minimum thickness limits that are pre-set by the operator.

- THICKNESS SAMPLE FOR ADJUSTING THE DELAY OF THE TRANSDUCER

Like other ultrasonic thickness gauges TM “NOVOTEST”, the Ultrasonic Thickness Gauge NOVOTEST UT-1M-ST has a thickness sample mounted on the device’s body, which allows the user to quickly set “0” (calculate the delay in the probe) when changing the transducers or the operating conditions of the device.

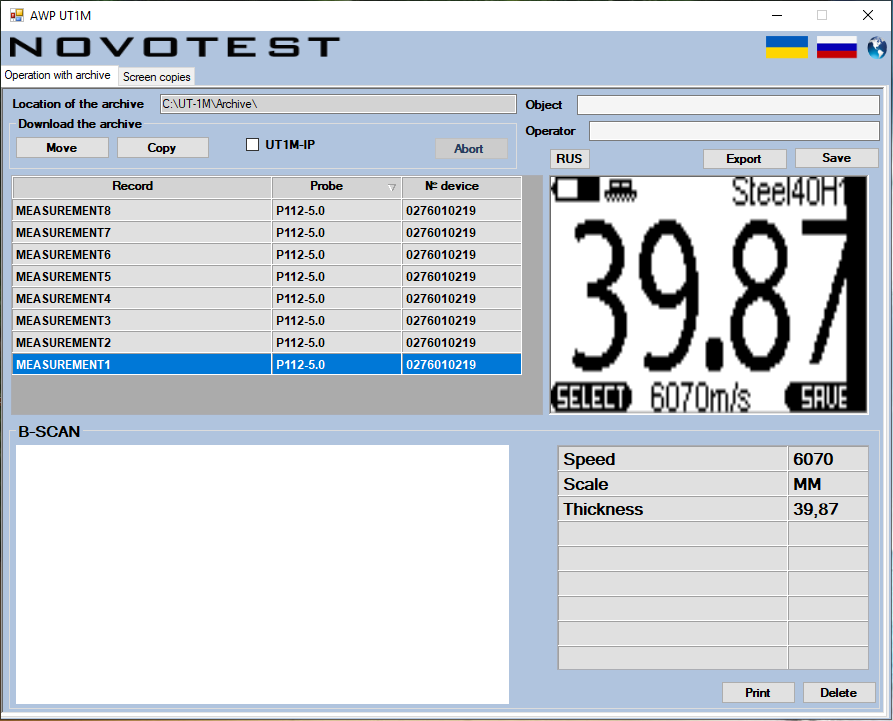

The device has a memory where the referencebook of the propagation velocities of the most common materials is stored, also the device allows user to save the settings of the transducers and measurement results, which can be stored both in the device and transferred to a PC using special software that is supplied with the standard Ultrasonic Thickness Gauge NOVOTEST UT-1M-ST set.

Advantages:

- Unique additional protection of metal housing;

- Saved data can be transmit to PC;

- Material selection and automatic setting of ultrasound velocity;

- Large graphic display of high contrast and backlight;

- Display of measured thickness in mm and inches;

- Convenient menu in the device;

- Wide choice of UT probes with preset settings in the device;

- Modes of statistical processing of measurements;

- Ability to restore factory calibrations;

- Ability to adjust all parameters of the acoustic path;

- Ability of further adjusting the user gain directly from the measurement mode;

- Wide range of testing;

- Mode of audible and visual alarm when break the preset ranges.

Measuring thicknesses range , mm:

|

0.5 … 500 or more

|

Probe dimensions, mm:

|

|

Diameter of probe contact area, mm:

|

|

Size of plate:

|

|

| Optional probes |

|

| Setting range of the ultrasonic velocity, m / s | 1000-9999 |

| Discrete readings on the digital indicator, mm | 0.1 |

| Response time, with no more than | 1 |

| Basic measurement accuracy, mm | ± (0,01 T+/- 0.05) |

| Echo-Echo mode (through coating measuring), max thickness of coating, mm | 1 (with optional Echo-Echo probes only) |

| Standards |

|

| Storage of measurement results | 256 |

| Overall dimensions, mm | 120x60x25 |

| Operating temperature range, ° C | -5 to +40 |

| Power supply | 2 AA batteries |

| Time of continuous work hours, not less, h | 10 |

| Weight of electronic unit with battery, no more, kg | 0.2 |