- Home

- About Us

- Products

- Rohmann Eddy Current

- Secu-Chek UV-LED Lamps

- Sonatest

- MR Chemie

- NOVO DR

- Hoffmann Tam Panels

- Desoutter Industrial Tools

- Novotest

- Integrated Design Tools (IDT Vision)

- Dakota NDT

- DeFelsko Corporation

- AVIONICS

- Sonotec Ultrasonic Solutions

- Sonotec Ultrasonic Hand-Tools

- G.A.L. Gage Company

- Western Instruments Inc.

- Esders Gas Technology

- Yoancomposite

- Hinode Electric

- Services

- News

- Contact Us

(65) 6878 0608  (65) 6878 0609 |

Overview

Ultrasonic Non-Destructive Testing (NDT) has helped engineers inspect composites and metallic structures across all industries for years. Whether it be traditional aluminium laminates, steel pipelines, pressure vessel shells or today’s more complex carbon fibre-based composites, ultrasonic NDT technology has the ability to inspect these parts and create complete inspection maps showing attachment locations, defects and wall losses. Comprehensive integrity reports can be generated, supported by imaging reports and CSV file exporting, data review is simple and repeatable.

Active with key industry leaders for more than 60 years, Sonatest is proud to present the RSflite linear scanning instrument.

Features

1) Scan, Record, Report…

WheelProbe2

Key features

- Light reinforced frame

- Patented rubber wheel

- Best acoustic’s on the market

Advantages

- Portable immersion quality A-Scan data

- Ease of use with a lightweight and ergonomic design

- Up to 0.8 mm near surface resolution

RSflite

Key features

- Linear Scanning

- Touch screen

- Portable device

Advantages

- User interface optimized for composite and corrosion mapping inspections

- Fast setup and operations

- Outstanding inspection speed

- Ready for all site conditions

UTmap

Key features

- T-Scan stitching

- Post analysis re-gating

- Automatic report

Advantages

- Data adjustments (gain, gates…) are easily done in post-acquisition

- Automatic measurements

- Fast data interpretation

- T-Scan gives freedom to properly reposition scans

2) Ultrasonic linear scanning solution

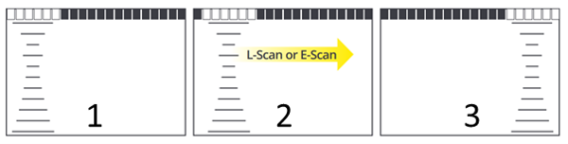

For composite inspection, a linear scan (L-Scan), sometimes referred to as an electronic scan (E-Scan), uses a group of elements of a linear array probe to pulse a single straight beam (1) , then another adjacent beam (2). This sequence is repeated equally over the full length of the array (3).

This ultrasonic NDT technique is particularly efficient to detect the most common defects inside composite structures and metallic plate / pipe as it covers large area’s rapidly, and generates high-resolution data sets and images.

3) Advanced solution benefits

- With a linear scanning workflow-oriented and simplified user interface; the complete solution optimises the training time and on-site performances within one machine

- The outstanding ultrasonic signal-to-noise ratio and patented WheelProbe2 rubber design is a system offering the best acoustic performances for composite inspection

- The combination of RSflite and WheelProbe2 makes the fastest portable immersion inspection system on the market

- The advanced UTmap analysis tools and unique C-Scan stitching capability increase overall productivity and enhance the inspection quality

Specification

| LINEAR SCANNING | CONVENTIONAL UT | |

|---|---|---|

| System Bandwidth | 0.2 to 23 MHz | 0.2 to 18MHz |

| Pulse Voltage | 100V – 50V ActiveEdge© | 400V – 100V ActiveEdge© |

| Channels | 128 channels | 2 channels |

| Gain Range | 80dB | 100dB |

| Max PRF | 50,000Hz | 20,000Hz |

| L-Scan Resolution | 1,2,3… element step & double res. | – |

| Data Throughput and Storage | 155MB/sec and 128GB SSD (no file size limit) | |

| Instrument Display | TOUCH 10.4″ wide, LED-backlit LCD, 1024 x 600 resolution | |

| Communication Ports | WiFi 802.11n, Ethernet Gigabits & 3 master USB2 | |

| Calibration Standards | ISO18563 (EN16392) & EN12668 | |

| Operating Time | 6.6h (hot swapable batteries) | |

| Operating Temperature | -10°C to 50°C (14°F to 122°F) | |

| Unit Dimensions | 115 x 220 x 335mm (4.52 x 8.66 x 13.19in) | |

| Weight | 4.80 kg (10.5 lb) no battery, 460 g (1 lb)/battery | |

| Analysis Software | UTmap for Windows® 10 & 64-bit OS | |

| Remote Control Software | Xpair for Windows® 10 OS | |